Engine and Transmission Tech

tips, technology, tools and techniques related to vehicle driveline components

|

MGB-FV8 Jacques Mathieu Alexandria, VA (299 posts) Registered: 09/11/2009 08:55PM Main British Car: 1977 MGB Small Block Ford, 331 Stroker |

Oil pump debate, pressure versus high volume?!?!?!?!

Since this section seems to be the "expert alley", I'm once more asking for some opinions on oil pump choices. I'm getting some machine work done and it was suggested that I replace my "HIGH VOLUME" oil pump with a "HIGH PRESSURE" oil pump.

His point was that an H/V oil pump with a standard pan runs the risk of sucking the pan dry under high RPM driving and also there are more chances of pumping too much oil to the upper valve train leaving the crank starving. He also stated that the small block Ford oil pump drive is a weak point and, since the pump gears are larger on the H/V pump it could snap. A short discussion followed but I sure that you all get the point. I'm sure that opinions may vary in preferences, and, any opinions would be greatly appreciated. |

|

Re: Oil pump debate, pressure versus high volume?!?!?!?!

They do make HD pump drive shafts. Check with Moroso. But if it's a Ford 302 Windsor you're working with, I don't know of oiling issues. It's a well-designed engine. A good, stock-type Melling oil pump will get the job done. Not everything on the engine needs to be hotrodded.

Pet peeves; underdrive pulleys and high output alternators, K&N air filters, Castrol Syntec motor oil. High volume oil pumps shouldn't be required on an engine that's built right. |

|

Bill Young Bill Young Kansas City, MO (1337 posts) Registered: 10/23/2007 09:23AM Main British Car: '73 MG Midget V6 , '59 MGA I6 2.8 GM, 4.0 Jeep |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Jacques, I'm certainly no expert, but it was my belief that high pressure pumps were called for when you had an engine with higher than normal bearing loads, say from very high compression or even adding some type of supercharger. The engine needed the higher oil pressures to prevent the loading on the rod bearings from forcing the oil from between the bearing and the journal. For high rpm engines where a lot of oil would be thrown off the crank a high volume pump was more called for. For a relatively standard compression V8 without a blower and operated in a range below 7000 rmp I would think that a good quality stock pump would be quite sufficient. Any higher pressure would only be bypassed back to the pan so nothing gained there and too high a volumn would also be wasted. I agree with Paul, a stock Melling pump should get the job done without adding any additional hp drain on the engine or stress on the oil pump drive.

|

|

ex-tyke Graham Creswick Chatham, Ontario, Canada (1166 posts) Registered: 10/25/2007 11:17AM Main British Car: 1976 MGB Ford 302 |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

What do you call high pressure? My 302 runs a stock Melling oil pump and typical dash gauge pressure readings are 85psi cold running, and 50psi hot idle - I've never felt comfortable with those kind of pressures but a local "expert" thinks they are normal for a SBF.

|

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6569 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Will someone kindly explain the difference to me? An oil pump is just a set of gears. If you want more volume you use longer gears. So does the high pressure pump use longer gears too? Otherwise how could you get any higher pressure? (Unless you are needlessly bypassing oil back to the pan)

JB |

|

roverman Art Gertz Winchester, CA. (3188 posts) Registered: 04/24/2009 11:02AM Main British Car: 74' Jensen Healy, 79 Huff. GT 1, 74 MGB Lotus 907,2L |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Jim and clan, B.O.R.'s with cam driven pumps,(dist. gear), have by-pass spring, built into timing cover/pump assembly. This dumps excess pressure to oil return."Hi Pressure" pump is, usually std. size gears, with stronger by-pass spring,(higher pressure). Of course this limits "maximum" pressure and will do nothing to help low pressure on say a motor with excessive clearances/throw-off. Hope this helps, roverman.

|

|

Dan Jones Dan Jones St. Louis, Missouri (311 posts) Registered: 07/21/2008 03:32PM Main British Car: 1980 Triumph TR8 3.5L Rover V8 |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

> Will someone kindly explain the difference to me?

Pressure is the consequence of pushing a volume of oil through a restriction. Most automotive oil pumps are positive displacement pumps with rotors that sweep out a fixed volume of oil each revolution. Spin the pump twice as fast and you'll get approximately twice the flow rate of oil. Pressure is a by-product of that flow into a restriction (bearing clearances, oil galleries, lifter bores, etc.) and the leakage rates . In an automobile engine, the leakage rate is a function of the engine clearances and increases with increasing engine speed (rotation). A certain pressure is required to overcome the centripetal forces flinging oil out the main and rod bearings. The higher the RPM or the larger the bearing diameters, the more flow rate required. In addition to rods and mains, there are lots of places where pressure can bleed off including lifter bores, rocker shafts/arms, oil pump housing, oil filter, etc. If the leakage flow rate exceedes the pump flow rate, then pressure can not be maintained no matter what the bypass is set at. Higher viscosity oil decreases leak velocity and thus leak volume due to usually higher compressive film strength as well as higher moment of inertia. As a general rule, it's a good idea to use the lightest weight oil that will maintain the desired oil pressure. Pressure drops wherever oil flow is bled off but the maximum supply pressure an oil pump can provide is set by a spring-loaded bypass valve. Once the oil pressure exceeds the spring pressure, the bypass opens. When that happens, little or no additional flow reaches the bearings. Note that some pumps will reach their maximum output at a relatively low RPM, say 2000 to 2500 RPM, with pressure dropping off at higher RPM. Also note that flow seeks the path of least resistance. If there is no resistance, there is no pressure increase. For instance, if you break a pushrod and the lifter pops out of place, a big hole is opened in the oil gallery that provide little restriction and oil pressure plummets like a rock. Over an engine's life, as bearings wear, restriction opens and oil pressure will be reduced. Also, as the oil pump wears, it may not sweep out as much oil (leaks it out). The goal of pressure fed lubrication is to float the rotating bits (rods, mains) in a film of oil so they don't touch on and wear against the stationary metal bits. The amount of lubrication pressure required is proportional to load and load goes up with RPM, so you want an increasing pressure with RPM. Smokey's old rule of thumb for small block Chevys was 10 psi per 1000 RPM. Load also goes up with power output. What an individual engine needs depends upon a lot of factors (bearing clearance, bearing diameters, bearing widths, oil pathways, leakage points, RPM, properties of the oil being used, temperature, how long the engine has to operate at a given RPM, etc.). If the engine is a bleeder, oil pressure at the rear bearings can be much less than at the front. In cases like that, you may need to increase the pump output (via a high volume pump and/or bypass spring) to compensate and/or restrict oil leakage (via precisely metered restrictors in the oil galleries, bushed lifter bores, tighter clearances, etc.). A high volume pump has larger (typically longer) rotors. A high pressure pump has a stiffer spring (can also be a shimmed spring). A high pressure and high volume oil pump has both. A standard volume pump with high pressure relief spring would give low pressure and flow at low RPM and high pressure and flow at high RPM. However, depending upon the engine and usage, a standard volume high pressure pump might not provide enough flow. In those cases, a high volume and high pressure pump is required. I can think of several situations where one might be of benefit. One is to provide adequate oil pressure over the life of an engine. New, the pump might be overkill but, as the engine (and oil pump itself) wears, the high volume pump may provide a measure of safety. Alternatively, you can run a heavier weight oil on high mileage engines, though this may increase wear on start up or while the oil is cold. Another is for engines that run at elevated RPM for long periods of time, like circle track or endurance racing, where oil temperature climbs and pressure drops. When the oil starts to get hot and thins out (like it might near the end of a race) the deeper gears are able to sweep out a larger volume of the thinner oil, providing better lubrication. Another application where high volume and pressure might be of use would be supercharged and turbocharged engines which can make greater power at relatively (compared to normally aspirated engines of equivalent size) low RPM. Long stroke stroker motors might also fall into this category. Also, any accessory that puts an additional demand on the oiling system would be a candidate for a high volume and high pressure pump. Examples would be external oil coolers and superchargers which feed off an engine's oil supply. Fast bleed rate lifters (e.g. Rhoads) may also require a higher pressure. Understand that high pressure and high volume volume are relative terms. At 33 PSI, the Buick 215 is at the low end of the range. Some engines like the Mitsubishi 4 cylinder in my sister's old minivan put out 100 PSI. A high volume/high pressure oil pump for a Buick 215 might be considered a standard volume pump in a Ford 351C. Remember that flow is proportional to the square of pressure. It takes quadruple the pressure to double the flow. For a specific engine, you really have to defer to experience. Do engines like yours, when used in a manner similar to the way you plan to use it, exhibit wear or failure patterns that might benefit from increased lubrication? In my admittedly limited experience, Buick and Rover V8's seem to be on the high end of the wear scale. Small block Fords tend to be on the lower end of the wear scale. If contemplating a high volume pump, you may want to consider a gated and baffled oil pan with greater than stock capacity. The trickest pump in the world won't save you if the oil sloshes away from the pick-up and sucks air. One of the guys in the Pantera club learned the hard way that a stock Pantera can pull 1G on a set of slicks. He also learned the oil will climb the side of the pan and starve the pick-up, resulting in a spun bearing. After rebuilding the engine, he now runs a flat bottom 10 quart road race gated and baffled oil pan. Pay attention to drain back as well. You can elongate and smooth the drain holes and valley. The old Boss 302 Trans Am motors even ran drain lines from the valve covers to the pan. > His point was that an H/V oil pump with a standard pan runs the risk of > sucking the pan dry under high RPM driving and also there are more chances > of pumping too much oil to the upper valve train leaving the crank starving. That can happen. > He also stated that the small block Ford oil pump drive is a weak point and, > since the pump gears are larger on the H/V pump it could snap. Heavy duty oil pump driveshafts are available from FRPP (Ford Motorsport) and ARP. In small block Windsors, I've seen the shafts twist up. On 351C Fords, I've seen the pin in the distributor gear tends to snap. In both cases, the problem is debris gets sucked up by the oil pump (usually a piece of old umbrella seal that gets through the bypass hole) that momentarily locks up the oil pump gears. > What do you call high pressure? My 302 runs a stock Melling oil pump and > typical dash gauge pressure readings are 85psi cold running, and 50psi > hot idle - I've never felt comfortable with those kind of pressures but > a local "expert" thinks they are normal for a SBF. Not in my experience. Either your gauge is wrong, the clearances are very tight, your bypass spring has been shimmed or you have a high volume pump (with the bypass shimmed). I believe the factory bypass pressure on my 5.0L Ford is around 40 PSI. In my daily driver 1987 Ford Mustang GT with 5.0L Ford, I run a blueprinted Mellings stock volume pump. It has over 220K miles and I set my bearing clearances on the tight side of the factory range. It has increased pressure over the stock oil pump but not so much that it drains the pan and it maintains pretty much the same oil pressure (around 50 PSI) whether hot or cold. Melling makes a very nice select blue print HV pump which is adjustable. Instead of a simple plug to hold the relief spring in, the hole is threaded and a hex screw fitted that allows you to set the bypass pressure. Alex Denysenko at Moneymaker Racing has a good price on these and keeps them in stock. I've got a similar set-up on my Rover V8 which is even nicer since it's outside the pan (mounted in the front cover). Dan Jones |

|

|

|

MGBV8 Carl Floyd Kingsport, TN (4615 posts) Registered: 10/23/2007 11:32PM Main British Car: 1979 MGB Buick 215 |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Whew, you had to ask, Jim! Thanks for typing out all that, Dan!

Somewhat OT, but Dan did mention 1G, I'm pretty sure I can pull 1G in my MG. |

|

Bill Young Bill Young Kansas City, MO (1337 posts) Registered: 10/23/2007 09:23AM Main British Car: '73 MG Midget V6 , '59 MGA I6 2.8 GM, 4.0 Jeep |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Carl, if you're pulling 1 G regularly I'd get yourself a baffled pan or at least an Accusump to protect that engine.

|

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6569 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Now there's a man who knows about oil pumps! Great post Dan, thanks for spending the time on it.

Jim |

|

ex-tyke Graham Creswick Chatham, Ontario, Canada (1166 posts) Registered: 10/25/2007 11:17AM Main British Car: 1976 MGB Ford 302 |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Quote: Wise words indeed......I distinctly remember one of our Spurious members changing bottom end bearings in the hotel parking lot after a few enthusiastic laps on the track near Terra Haute. |

|

roverman Art Gertz Winchester, CA. (3188 posts) Registered: 04/24/2009 11:02AM Main British Car: 74' Jensen Healy, 79 Huff. GT 1, 74 MGB Lotus 907,2L |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Honestly, I don't know how "flat" motors even deal with lateral G's, with out oil accumulators or dry sumps. I suspect the 90 deg. motors also help return oil, defy gravity and climb away from sump, hence the story of TA. 302's having oil returns from the valve covers. I think we know to "watch" our main/thrust and rod side clearances ? Too much on the rods will only aggravate the problem and "flood" the cylinder walls. roverman.

Edited 1 time(s). Last edit at 03/31/2010 08:39PM by roverman. |

|

MGB-FV8 Jacques Mathieu Alexandria, VA (299 posts) Registered: 09/11/2009 08:55PM Main British Car: 1977 MGB Small Block Ford, 331 Stroker |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

WOW! Thanks everyone. Dan, you went all out to clear the issue. Actually I'm going to keep the oil pump that's in the engine now; it turns out to be a fairly new Melling H/V oil pump with the adjustable relief valve. I've ordered a Canton 6 quarts oil pan to satisfy the hungry beast.

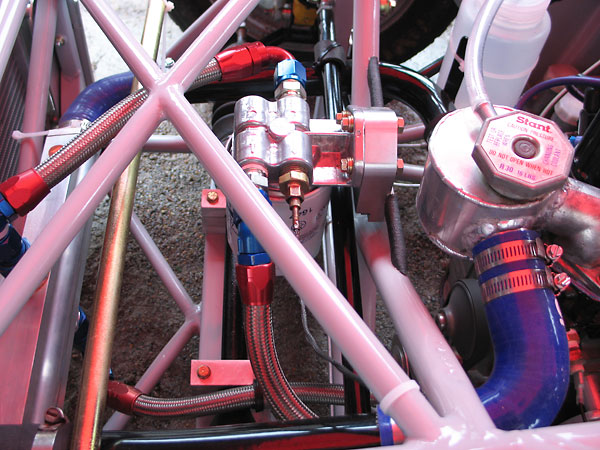

I'm also a firm believer in using an oil cooler (water to oil) to stabilize the oiling system and maybe some sort of remote oil primer to protect the bearings under cold start as Art indicated. Here's a photo of the oil cooler, it came out of a wrecked late model Crown Victoria police interceptor. It also helps the radiator draw air better than using an air to oil cooler. |

|

Re: Oil pump debate, pressure versus high volume?!?!?!?!

The oil to coolant cooler works much better than the oil to air cooler. Another way to cool the oil is to use a radiator from a car with an automatic transmission. Run the oil lines through the trans oil cooler. As you suggest, it helps stabilize the oil temperature. That PI oil cooler is probably a better bet, probably has bigger oil lines.

|

|

|

|

Moderator Curtis Jacobson Portland Oregon (4636 posts) Registered: 10/12/2007 02:16AM Main British Car: 71 MGBGT, Buick 215 |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

If wrecked Crown Victoria police interceptors aren't commonly found in your neighborhood... I think you can buy a similar oil-to-water heat exchanger new.

This is a Laminova C43 series cooler - made in Sweden - as used on Craig Chima's Ginetta G4 race car  |

|

MGBV8 Carl Floyd Kingsport, TN (4615 posts) Registered: 10/23/2007 11:32PM Main British Car: 1979 MGB Buick 215 |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

"I distinctly remember one of our Spurious members changing bottom end bearings in the hotel parking lot after a few enthusiastic laps on the track near Terra Haute."

Graham, I remember, as well, it was Mike Moor. I don't believe that's what caused it, though. |

|

tr6turbo Dale Knapke Sidney, Ohio (169 posts) Registered: 08/24/2008 09:44PM Main British Car: 1972 Triumph TR6 Ford 2300, 4 Cyl Turbo |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

The 87 and 88 Ford Thunderbird Turbo Coupe has a very nice oil to collant cooler that is easy to adapt to a remote filter unless you have a Ford then it can mount to the engine. My bet is tht it is the same one the interceptor uses.

|

|

MGB-FV8 Jacques Mathieu Alexandria, VA (299 posts) Registered: 09/11/2009 08:55PM Main British Car: 1977 MGB Small Block Ford, 331 Stroker |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Hi Dale, the cooler is not even close to the Crown Victoria. Take a look at my posting above, the photo is the one with the cooler hanging in front of the rack & pinion. The hoses are not attached yet but it should give you a general idea of the cooler seize. The T-Bird cooler mounts sandwiched between the block and the oil filter and it also has a much smaller cooling capacity. Having an oil cooler also gives you the ability to run thinner oil for faster cold start lubrication and also reduces engine drag for efficiency which in turn increases (by a small amount) MPG and HP.

The modern Crown Victoria Police Interceptors run a 4.6 Liter OHC modular engine and requires 5W20 oil. What I find amazing is that the crankshaft and rods bearing clearances are very narrow compared to old school performance engine build up. IMO, it definitely needs to run thinner oil to clear these small passages and it also needs a cooler that can meet the task to stabilize the oil; the oil pump also ought to be also an interesting subject/choice. Iím not a Ford modular engine expert other than the fact Iíve read that Ford spent one billion dollars to develop their new modular power plant. Cubic inch for cubic inch, it out performs their historical pushrod line of engines. Another reason that I prefer this type of oil cooler (coolant to oil) is that it also keeps the oil at engine operating temperature in extreme cold weather as it does in hot weather. Of course, both type can host a cooler (cold) by-pass valve (part of the C/V system) to avoid circulating oil through the cooler under cold weather but, it adds more hardware, besides, most of us enjoy cruising our pocket rockets throughout the T-shirt weather seasons (IMHO). |

|

MGB-FV8 Jacques Mathieu Alexandria, VA (299 posts) Registered: 09/11/2009 08:55PM Main British Car: 1977 MGB Small Block Ford, 331 Stroker |

Re: Oil pump debate, pressure versus high volume?!?!?!?!

Most of you may already know this, but, words of caution for anyone increasing the oil pump volume/pressure should be to install "screw-on" oil gallery plugs. The OE small pressed-on plugs could blow out from the block causing an oil pressure failure.

My 2 cents! |

Sorry, only registered users may post in this forum.