Engine and Transmission Tech

tips, technology, tools and techniques related to vehicle driveline components

|

Re: Ford 9 inch components in an MGB axle?

|

|

Re: Ford 9 inch components in an MGB axle?

I should have the spool back on Friday this week :)

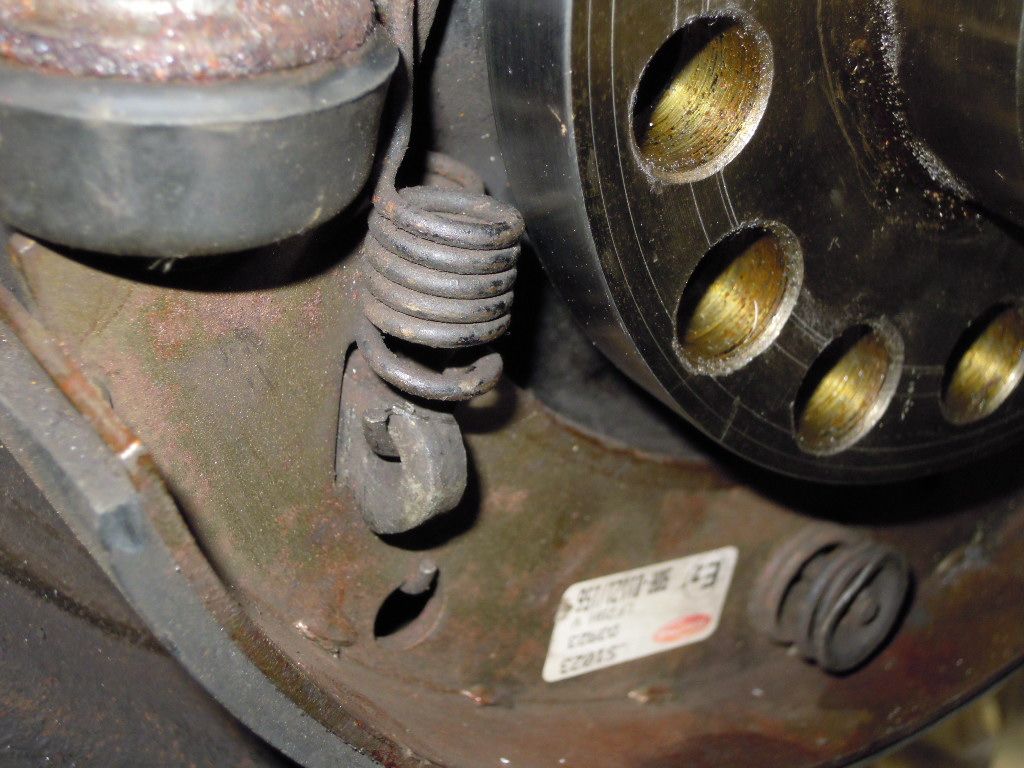

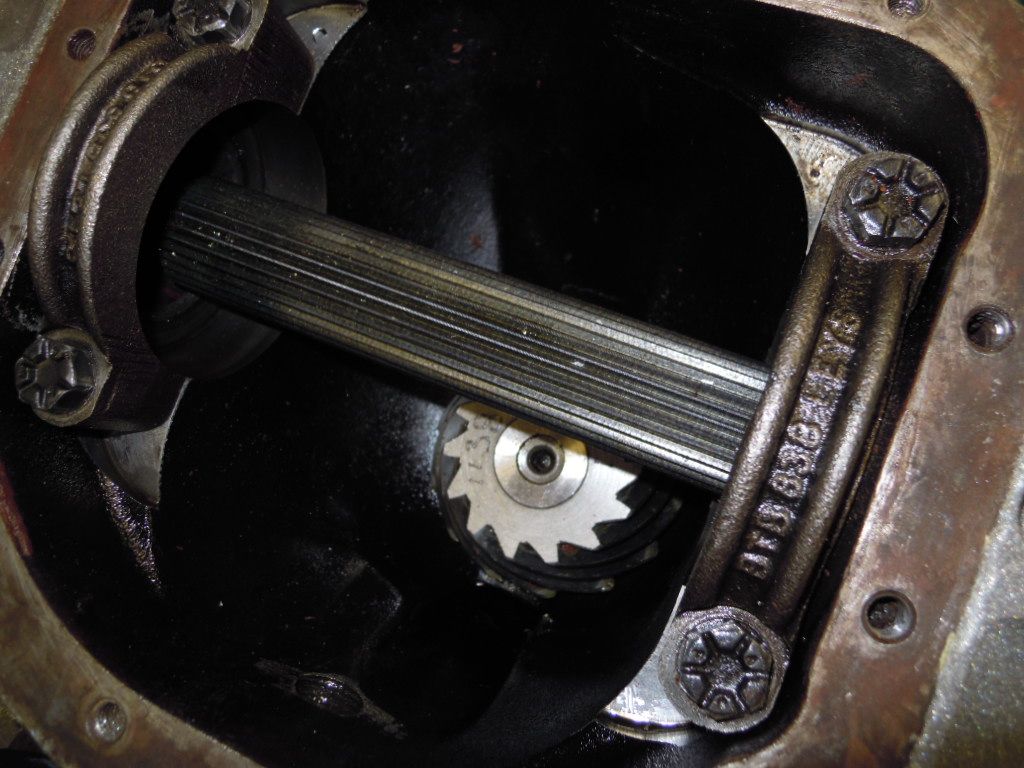

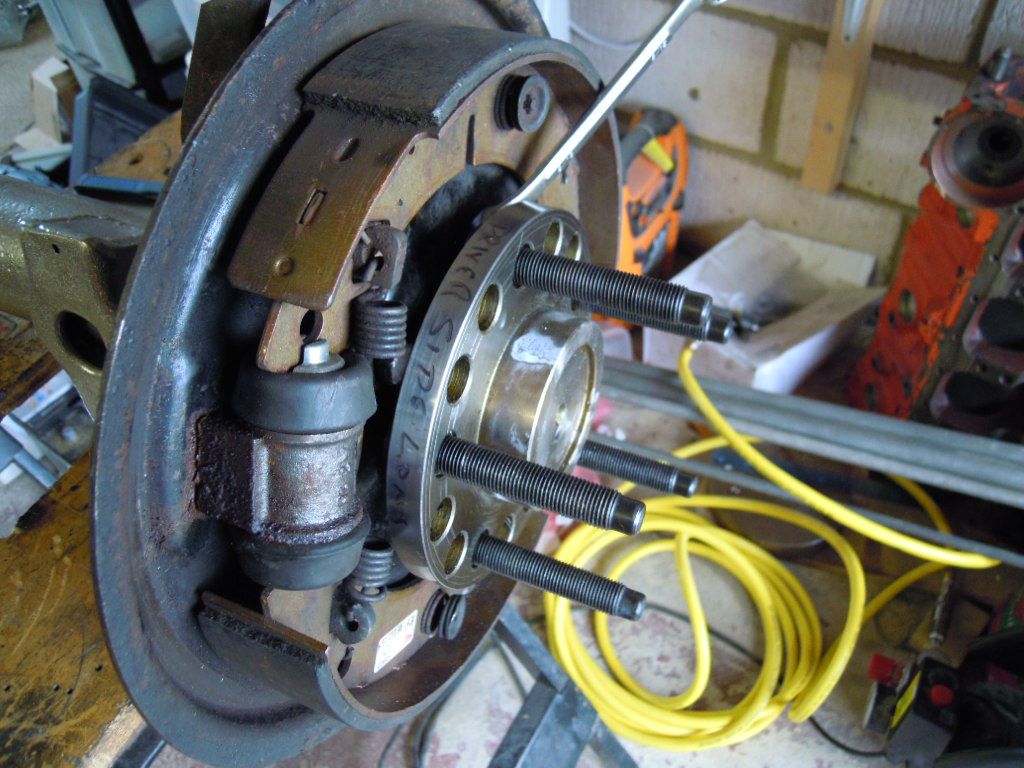

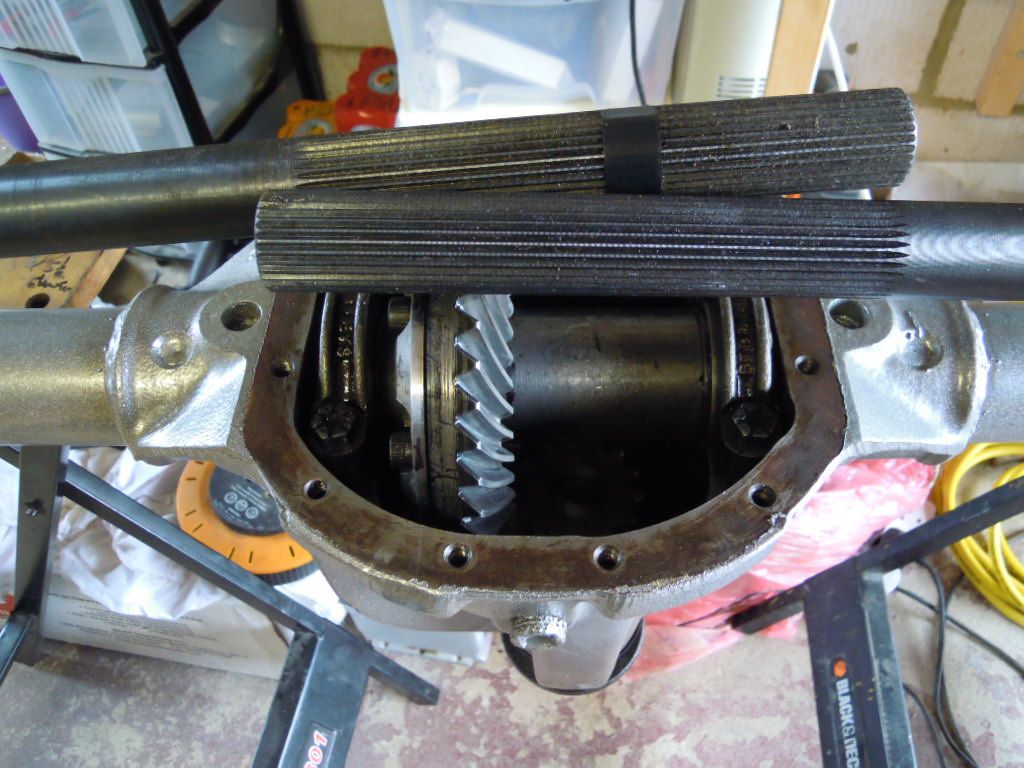

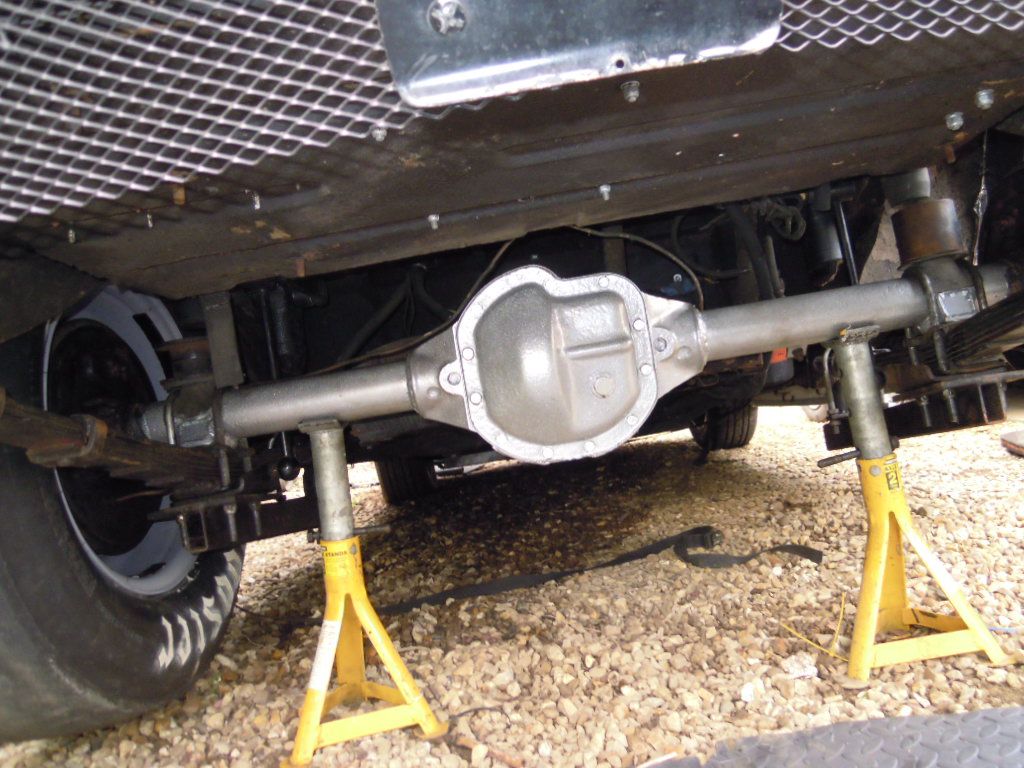

I've decided to use cap head bolts so I dont have to take so much metal out of the spool flange for hex head bolts and a socket. Not sure what the old bolts are regarding strength. I assume 8.8 or similar. The cap head allen bolts are 12.9 rated so should be ok? I'm still waiting for my wheel studs, but a friend dropped round a set of used studs from his Ford axle in his MG Magnette tonight so I can drop them in loose for lining up the drums on the drive flanges so I can drill and tap for drum retaining screws :) This weekend I will be fitting the spool and crown wheel / ring gear so I can do the checks to make sure the gear mesh is still as it should be. If all the machine work is correct the sshould mesh within a few thou of where they were originally. It wont be long before I have to take the cutting wheel to the shafts to make them the right length. Having looked inside the spool I can see that it was splined all the way through, and then the splines have been trimmed back to give a lenght of splining in the spool which sits with even splining either side of the spool flange. I guess this is done so each shaft (despite being odd lengths) has the same amount of spline contact at the same point from the area central to where the power is transferred into the spool ?? As you can see in the last picture, the axle case has been sandblasted and powder coated to tidy it up a little. |

|

mgb260 Jim Nichols Sequim,WA (2463 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford 9 inch components in an MGB axle?

Perry, I know you are not done but, the thick part of the spool should be spot faced to have a flat surface under the allen head. The ones that intrude on the holes should have a countersunk hole and spacer under the heads.

|

|

Re: Ford 9 inch components in an MGB axle?

Thanks Jim!

Thats on the menu for this week. I'll drop the spool back to the machine shop after work tomorrow and hopefully he will get it done in a couple of days. I have also decided to drop the idea of making shims to go inside the shaft bearing retainer caps to make up the difference in thickness between the Ford bearings and the MG bearings. I'm just going to trim 1.25mm off the mating faces of the bearing retainers so they will bolt up with no shims inside. I'm going to use ARP washers under the allen bolts I think. I have spares on the shelf from old ARP head stud kits that I only used 20 bolts from. So I sohuld have at least 16 spare washers in the stock somewhere? Wheel studs should be at the shop on Wed so by Thursday I may be able to start getting the brake ends fitted and the bearings pressed into place. I'm in no rush at the moment. I still have 6 weeks in hand too make sure all this prototype kit goes together as best it can so I can be ready for testing in early June. I have learnt so much in the last 2 months while I have been playing with the rear end, and its been a lot of fun for me to be honest. I cant believe how calm I am about having missed so much racing since the 19th Jan when I broke it again. Normally I would be getting quite twitchy, but as the end result should be a sub 9.5 pass after shakedowns I'm happy to wait. An dif that goes ok I'm going to start looking at adding some power and then start aiming for the 9.4's :) Regards to all from a lovely warm and sunny UK today 67 degrees and no wind.. Hell, I even cut the grass today..... Perry |

|

|

|

mgb260 Jim Nichols Sequim,WA (2463 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford 9 inch components in an MGB axle?

Perry, When you get ready to bolt up the Allen's for the last time, you should use blue Locktite on the threads and torque in back and forth pattern in 3 stages.

|

|

DiDueColpi Fred Key West coast - Canada (1365 posts) Registered: 05/14/2010 03:06AM Main British Car: I really thought that I'd be an action figure by now! |

Re: Ford 9 inch components in an MGB axle?

Perry,

Your determination and unyielding drive to complete this project is an inspiration. I particularly enjoy your problem solving and "oh that won't work, we'll just do this instead" attitude. I can hardly wait to see it run. Well done. Cheers Fred |

|

MGBV8 Carl Floyd Kingsport, TN (4512 posts) Registered: 10/23/2007 11:32PM Main British Car: 1979 MGB Buick 215 |

Re: Ford 9 inch components in an MGB axle?

"...my friends Methanol slingshot"

Would that be the front engine Digger in one of the pics? Any action video of it? Looks like a fun ride! |

|

Re: Ford 9 inch components in an MGB axle?

Hi Carl

Yes, thats it in the picture :) I have some vids I'll dig out soon. We havent made a full clean pass in it yet as we are still learning how to drive the thing. The best run was a sloppy launch on the transbrake at 1800 rpm which put the front wheels in the air. He then backed off and tickled the pedal to get it running straight. But each time he hit the power the rears just ballooned and let go. He pedalled it 4-5 times and backed off each time. It still ran a low 10 though. I'm sure when we have it dialled in and working ok it will run high 7's with no issues. The next 6 or 7 months should see the car running ok, and I will be driving it again for some shakedown passes. The methanol engine has been a long and interesting learning process for the last 2 years. I thought my carb system was basic. But the mechanical injection setup on the Slingshot makes my fuel system look positively cutting edge :) So many pipes and by pass valves !!! My wheel studs and nuts have now arrived from Summit. When I opened the box I thought they hade made a mistake as there were 4 bags of nuts, with 4 nuts in each bag?? Then I remembered that I now have 5 nuts per wheel. I then thought how odd it was that there are only 4 nuts per bag. The wheel studs come in packs of 5 but the nuts in packs of 4? I'm not sure how expensive these items are in the USA. But the 10 studs and 12 nuts were delivered today for the sum of $147.96 inc of all taxes etc. I'll be back in the Slingshots garage tomorrow for more trial fitting of my spool.... |

|

Re: Ford 9 inch components in an MGB axle?

|

|

|

|

Re: Ford 9 inch components in an MGB axle?

|

|

Re: Ford 9 inch components in an MGB axle?

Did some shakedown runs today and the axle conversion seems to work ok ??

Long story short! Several test runs on boost only gave me a string of 10.8's. Turned the gas back on with real gentle launch setting and long build time got me back in the 9's with no drama. I have added 3 degree's of ign timing as the engine has run safely retarded for nearly a year now. The result is slower 60 foot times of 1.5's instead of my usual 1.3's. But the added timing makes the engine pick up and rev better. Even with the 1.5 60 foot times I ran just a tenth slower with a 9.7 on my quickest run, BUT I ran faster with 141mph as opposed to my old 137-138mph 9.6 second passes. I will drain the axle and open it up this week to check it out. If it looks ok I can get the car ready for next weekend which is two days of RWYB when i will think about adding more power for the launch ?? Pic shows less air with the gentle launch, and the vid of the slower 9 shows just how soft the launches were today, even with the better MPH !! Sorry!! the vid is a silent slo mo. But the launch shows good info. The rest is slow and boring.

[www.youtube.com] |

|

Re: Ford 9 inch components in an MGB axle?

I drained the diff oil and saw nothing in it. I took the back cover off and scooped out what oil was left laying inside on my finger. I found some microscopic shiny particles on my finger. This does not worry me to be honest :) The moving parts are all 39 years old and I have upset them from their old resting place, so I guess they need to settle back into the new resting place now?

The wear marks on the ring gear are all central on the teeth which I'm happy with. The slop between ring and pinion can be felt when I try to rotate the propshaft back and forth, but it cant really be seen. I can just feel a little something when I wiggle the propshaft. ? I have to say that I'm a litte concerned with the amount of slop between the drive shafts and spool when I try to turn the wheels. But my mate with the Slingshot says this is the amount of play he has on his new setup so I should not worry ?? The diff now has new oil and is ready for next weekend. After 3 months of no racing I now have two whole days of track time coming up. And I am hoping to come home with a 9.59 second ticket on Sunday :) |

|

mgb260 Jim Nichols Sequim,WA (2463 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford 9 inch components in an MGB axle?

Perry, Sounds like you eliminated a weak link with the rear axle swap! Good luck and keep us posted.

|

Sorry, only registered users may post in this forum.