Engine and Transmission Tech

tips, technology, tools and techniques related to vehicle driveline components

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6469 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Ford 9 inch components in an MGB axle?

I'd say the 300-350 range is going to be a little iffy myself but it's a judgement call. If the helix angle matches the 7.5 it is just possible those and the carrier could be used in the MGB housing, eliminating the machine work and making the swap to new gears, a cheaper posi, and stronger axles a distinct advantage. It's worth looking into.

Jim |

|

Re: Ford 9 inch components in an MGB axle?

Hi Folks!

There seems to be a little confusion on this thread but its mostly on the right lines. I'll try to be brief: But anyone that knows me already knows that this wont be brief :) The crown wheel is 7.5" O/D. This is the same for the V8 diff and the 1800cc diff. Both crown wheels have 43 teeth. But the angle of the teeth on the V8 version is steeper to accomodate the angle on the bigger V8 pinion which has 14 teeth as opposed to 11 teeth on the 1800cc pinion. My first thought was to fit 31 spline side gears into the original diff cage. As I use a welded diff this was going to be done by cutting some metal off the sides to make two flats so the gear would slide into the cage. This was not a bad idea, but the messing around involved in boring out the side bores of the cage were going to mean making some tools for the lathe. While I was playing with a spare axle in the garage I remebered that a friend had given me a 9" spool last year as something to play with. That was easy to fit. The axle tubes are more than big enough to take the thicker shafts. My man at the shop has reduced the raised section of the spool so the MGB crown wheel / ring gear will fit. In order to get the mesh right he is skimming 5mm off the face of the spool. And grinding 3mm off the mating face of the crown wheel. He said the spool was very hard material. And the crown wheel is harder, hence the surface grinding required. The Shaft bearings for the Ford 9" shafts are a stock item where I work so they are free. The bearing size is what Moser call "Big Ford" ? The O/D of the ford bearings is 1mm bigger that the stock MGB shaft bearings. So my friend at the machine shop has made up a mount so the bearings can go on his paralell grinder / tube grinder to trim them down. The bearings on the 9" spool are smaller in O/D than the MGB bearings. The bore on the MGB diff bearings is just a few thou smaller than the Ford. So I cleaned up the ends of the spool after cutting off the Ford bearings and heated the MGB bearings in the oven to 220C. They dropped on easily with just a light tap from a hammer with a block of wood. I dropped the spool in and only needed to trim 25thou off one of the side shims (which were 132thou) to make it sit nice and snug. The shafts I have are multi drilled. I'm going to use the 5x4.5" holes. I need to trim the O/D of the wheel flanges down to fit into the recess on the brake drums so I can get them fitted flush. The shafts are 30" with 8" of splines cut into them so I can trim them to length as required. I'm going to re drill the brake drums to 5x4.5" and then find some 5 stud steel rims that I can get banded to the backspace and width I want to fit the slicks. This weekend I'm going to clean up the casing and weld the tubes onto the diff housing. The brake assemblies will be re fitted as the wheel flanges will sit in just like the originals. So its just wheels I need to look for now. Regarding the MGB axle and its strength!! This is the original MGB V8 axle from 1975. It had 90,000 miles on it when I bought the car back in 1999 and used it as a show car. The car has been drag raced since 2004 when it was a 3500 with stock tranny and nitrous. In 2006 I fitted the TH350 gearbox and a 4.6 engine with nitrous. We ran like this for 5 years until I started snapping the stock shafts. I then had the MGB shafts copied by Moser and they were very strong. However, they were machined down to 1" at the drive end to fit the stock diff. They lasted really well I think. Up to the point before I fitted the blower I was running the engine with a 600DP carb and a 250 shot of gas which made 390hp on the dyno with 602 ft/lbs of torque. To be honest, the stock MGB shafts would have held this on the dyno as the power build is quite gentle to stop the slicks overheating. But they would have broken on the launch in the strip. So I now had the 4/71 fitted and the Moser copy shafts. And I kept adding boost and nitrous until I got down to 10.1's on the drag strip. No problems with the shafts or the diff. But con rods were now an issue. So I scrapped the 4.6 and found a 3.9 to work with. I wont go into too much detail about the engine. But suiffice to say it has a lot more grunt than the old 4.6 did. When we took the new engine for shakedowns it ran 9.8's on the strip. Then I did a few tweaks and got it on the rollers. With 12psi and a 175 shot she made 525hp with 545 ft/lbs on the dyno with AFR rich and timing knocked back around 10 degree's from where I think it will end up. This again was with a gentle power build on the dyno. The Moser copies were holding up fine with months of 9.6's on the strip while I was testing and data logging. The car was so predictable that almost anyone could jump in and run a 9.6 second pass with ease. The car was put away last November and was then hauled out for some use on 19th Jan this year. First pass was a 9.6 as usual. Then I decided to add 2.5 degree's of timing and try again. This time the engine came to life and broke a shaft and twisted the other within 2 feet of leaving the line. So the Moser copies had now been tested to their limit. After some talks with folk in the USA it seems that the difference in thickness between my old Mosers and the Ford 31 spline (at the drive end) would yield around 89% more strength on paper. So the obvious thought was to buy a Ford 9" axle and have it shortened to suit my car and have all the brackets welded on etc so it would drop in. And I would want a gear set as close to 3:1 as I could get. This would run out to at least $5000.00 over here. But $250 for shafts with $290 for shipping I have what I need to work with for a lot less than a full axle. Which is why I'm doing what I'm doing now. :) I'm under no illusions regarding the diff. I know that improving the shafts will now just go backwards through the drive train to find the next weak link. That may be the diff gears, the prop shaft or the gearbox which has now been dragged for 8 years ?? If I add on the $400 that I will pay my friend at the machine shop for doing all the work I'm still under $1000 for the whole job. Track info to date is: 60 foot = 1.37 seconds The rest you can see here: [www.youtube.com] And the first test run this year with the new exhaust sytem fitted: [www.youtube.com] And what happened when i added 2.5 degee's of timing :) If you look closely you will see that the new Hoosiers dead hooked and the front left wheel was off the ground immediately. As you can see I backed off the pedal within a few feet. I coasted over the 60 foot beam in 1.40 seconds :) I normally only run high 1.3's with full power in the 60 foot. So hopefully the new shafts will help me go sub 9.5 this year ? [www.youtube.com] Edited 2 time(s). Last edit at 03/14/2014 06:28PM by perrymgbv8. |

|

mgb260 Jim Nichols Sequim,WA (2463 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford 9 inch components in an MGB axle?

Hey Perry, Thanks for keeping us posted! I just signed on the V8 board and I find you over here!

|

|

Re: Ford 9 inch components in an MGB axle?

No problem Jim

I've been quite busy and not had much time to come on here to update :) Perry |

|

Re: Ford 9 inch components in an MGB axle?

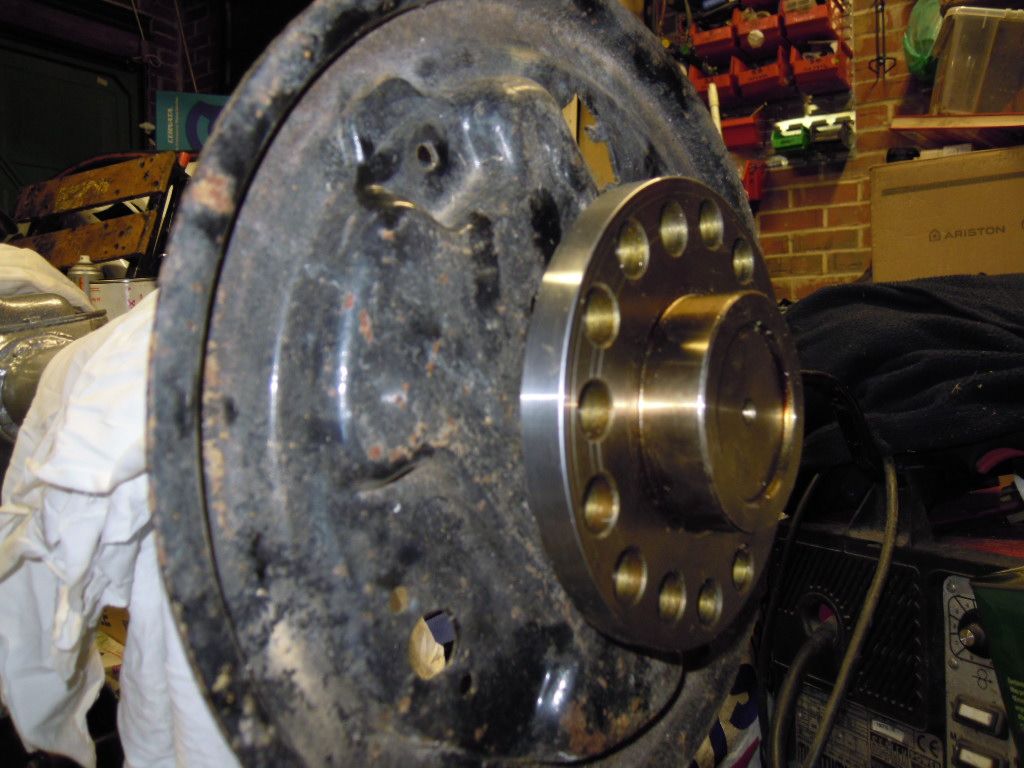

Small update from today!

I welded the axle tubes onto the diff casing and straightened out the bent leaf spring mounts. Tomorrow I will weld in some fillets to make the spring mounts stronger as they seem to be suffering from the leverage effect from the slapper bars on the launch ? Hell ! I may even clean and paint the axle case :) |

|

Re: Ford 9 inch components in an MGB axle?

|

|

|

|

mgb260 Jim Nichols Sequim,WA (2463 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford 9 inch components in an MGB axle?

Perry, Welding the tubes to the housing is always a good idea. The small rosette welds holding the tubes in place aren't strong enough for high HP where you get traction. Thanks again for keeping us posted.

|

|

Re: Ford 9 inch components in an MGB axle?

I'm now looking into trimming the wheel flanges down to fit the recess in the MGB drums. But as the stud holes in the flanges are 15mm that only leaves about 2mm of metal around the edge if I use the 5 x 4.5" holes.

The MGB studs are obviously smaller, but I havent measured yet ! I'm not too concerned about the lack of metal outside the holes, but I'm wondering if the studs when pressed in will mis shape the thin outer wall and stop the brake drum dropping on? If this does happen I can weld the studs onto the flange and then turn any extra metal off the outer edge of the flange. I would like to keep my original MGB rear brakes if I can without compromising the strength of the wheel flanges. OR! I could see if I can find some brake drums with 5 x 4.5" bolt pattern that are 10" x 2" which is what I think the MGB brakes are ? Time for some research methinks ?? :) |

|

Re: Ford 9 inch components in an MGB axle?

Thanks Jim!!

Thats good info mate :) My friend has an old Ranger in his yard ready to break ? Perry |

|

Re: Ford 9 inch components in an MGB axle?

Dag nabbit!! He sold the Ranger :(

I'm going to find some cheap wheels to get me by for the near future now. Because I have a dream of seeing Cragars on the MGB now :) I've loved the look of these wheels since I was a kid. And as my 60th Birthday is only 5 years away I feel I owe it to myself to have Cragars on the car in 2015 or sooner ;) 8-9" Cragars on the rear with Hoosier slicks and maybe skinny Cragars on the front or some centreline front runners with 4" tyres would look so cool I think .. That would make one hell of a track picture at launch with wheels in the air ?? So now I have a plan for the final look of the wheels. but first I need to get some rims so I can go racing when the axle is finished. |

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6469 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Ford 9 inch components in an MGB axle?

Perry, you might want to reconsider those Cragars. They rust, and there's not much you can do to stop it. Matter of fact, despite their popularity (or maybe the cause of it) they really are some pretty cheap wheels. I put a set of brand new ones on my MG way back when and within a year they were going bad. By the time I could replace them they had turned brown and flaky. The joint between the rim and center looked none too solid too.

Now for a really GOOD drag wheel you might look at the polished Centerline Classics. Forged, around 11 lbs each (light as you can get) and strong. Keep 'em shined up and they'll look good forever. Only flaw is the silicon center seal but that can be removed and re-sealed if it starts to leak. Jim |

|

MGBV8 Carl Floyd Kingsport, TN (4512 posts) Registered: 10/23/2007 11:32PM Main British Car: 1979 MGB Buick 215 |

Re: Ford 9 inch components in an MGB axle?

Cragars have an aluminum center. That's the part that the chrome flakes off of first. Been known to break.

Personally, I like Weld Superlite II or Pro Stars for a good looking drag wheel. [ba5ff4f7910368ced8d0-fdac4e44cc35e2759af294e7b095ba3d.r33.cf1.rackcdn.com] [ba5ff4f7910368ced8d0-fdac4e44cc35e2759af294e7b095ba3d.r33.cf1.rackcdn.com] |

|

Re: Ford 9 inch components in an MGB axle?

Thanks Jim and Carl.....

Possible disaster averted eh?? Now I have more possible wheels to look at :) I'm out for a days bracket racing tomorrow with a normal car. But when I get back I'll do some pics of the axle case in powder coat and the next alteration that is required to the 31 spline shafts ?? Regards Pel Edited 1 time(s). Last edit at 03/28/2014 05:29PM by perrymgbv8. |

|

|

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6469 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Ford 9 inch components in an MGB axle?

Welds are heavier.

Jim |

|

mgb260 Jim Nichols Sequim,WA (2463 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford 9 inch components in an MGB axle?

Perry, Check out these wheels: [www.team3wheels.com]

|

|

mgb260 Jim Nichols Sequim,WA (2463 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford 9 inch components in an MGB axle?

Perry, C clip eliminator doesn't apply to the 9" or MGB pressed on bearings. It is for the 7.5/8.8 to eliminate the C clips on those axles. For the dragstrip on those axles are OK, but leak if doing corners. Best to convert those axles to 9" press on bearing axle retention. No welding necessary, .003 interference press fit and 4 bolt flange keep the axle in. What outside axle bearing did you find that is MGB OD and large 9" ID(.003 smaller than shaft).The spacing of axle flange has to be right for whatever brakes you are using. Might want to copy MGB stock flange to backing plate.

Edited 3 time(s). Last edit at 03/30/2014 05:40PM by mgb260. |

|

Re: Ford 9 inch components in an MGB axle?

Thanks Jim

The bearings I have are the ones specified for the shafts which are SKF 6307-2RS-3C. These are a stock item at work so they are free to me. This bearing is 1mm larger in O/D than the MGB stock bearings and 1mm thinner. My mate is going to grind the 1mm off the O/D and make a pair of 1mm shims this week. To get the mating face of the wheel flange in the right place he will remove 9mm of the raised shaft section just behind the wheel flange to extend the section where the bearing will press on. Thats good that the press fit will do the job :) The existing seal in the MGB bearing retainer plate fits quite well over the thicker section of the shaft as well. I may get some new ones or even take the shaft and retainer to a local bearing and seals place to see if they have anything that will fit a little better. I've just ordered 10 wheel studs from a local supplier. The holes in the wheel flange are 0.590" which he says is a stock item at the race shop :) So things are moving on nice and steady now!! I have to work all next weekend but I'm hoping to have the machine work done middle of next week so I can start assembly and maybe have it together over the Easter holidays. Fingers crossed :) Regards Perry |

Sorry, only registered users may post in this forum.