Engine and Transmission Tech

tips, technology, tools and techniques related to vehicle driveline components

|

mgb260 Jim Nichols Sequim,WA (2464 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

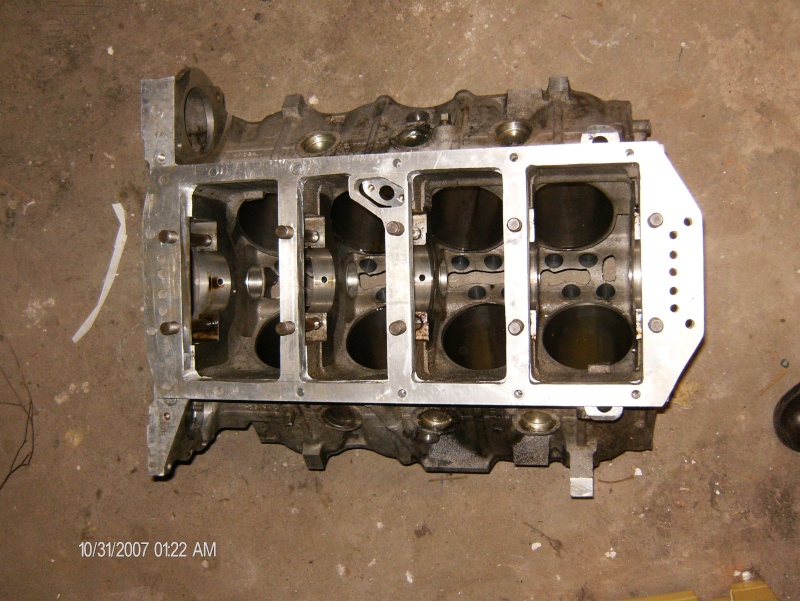

Ford style girdle

The Ford style girdle fits inside the pan and just ties the main caps together. Would be easy to make for a Buick/Olds 215,300,340 or early Rover.Of course it would'nt need the oil pump kick out and would be straight like the other end.Here is a picture:

Edited 4 time(s). Last edit at 12/19/2009 05:11PM by mgb260. |

|

roverman Art Gertz Winchester, CA. (3188 posts) Registered: 04/24/2009 11:02AM Main British Car: 74' Jensen Healy, 79 Huff. GT 1, 74 MGB Lotus 907,2L |

Re: Ford style girdle

Jim and clan, thats great for a sbf. Why do we "need" this for a 4.0/4.6L? 215 and 300, maybe, after-all , Repco used it, for formula 1. We've heard reports of late Rovers with stock crank and rods, living with a 400 hp. squirt of NO2. How many horses we tryin to control here? roverman.

|

|

mgb260 Jim Nichols Sequim,WA (2464 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford style girdle

I was thinking only 215 and 3.5 and 3.9 Rover.Oh, and 300 and 340 like Jim Blackwoods. 4.0 and 4.6 have crossbolted mains so are fine.Edited earlier post.

Edited 3 time(s). Last edit at 12/19/2009 05:12PM by mgb260. |

|

WedgeWorks1 Mike Perkins Ellicott City, Maryland (460 posts) Registered: 07/06/2008 08:07AM Main British Car: 1980 Triumph TR8 3.5 Litre Rover V8 |

Re: Ford style girdle

I see this working for an engine that has tall bearing caps that are above the oil pan mounting flange which is better than nothing. The rovers with 2 main bolts for competition use a gridle that goes between the pan and the block with the caps incorporated. The rover 4 bolt mains really doe not need a girlde. I can see it used for high rpms. Here is something Im going to try on my next engine build (high rpms hint..hint....)

|

|

mgb260 Jim Nichols Sequim,WA (2464 posts) Registered: 02/29/2008 08:29PM Main British Car: 1973 MGB roadster 260 Ford V8 |

Re: Ford style girdle

Cool Mike! That will add some ridgidity ( don't know if that is a word or not) to your monster bores.

Edited 1 time(s). Last edit at 12/19/2009 05:39PM by mgb260. |

|

roverman Art Gertz Winchester, CA. (3188 posts) Registered: 04/24/2009 11:02AM Main British Car: 74' Jensen Healy, 79 Huff. GT 1, 74 MGB Lotus 907,2L |

Re: Ford style girdle

Thanks for the "pic", Mike. I hope your not giving too much away? lol. May want to consider having the tops of main caps,(as in your ONE spy photo), fit up into a "register/counter groove" in underside of girdle. U-no for an undisclosed amount of rpm, hp, fuel, boost and anything else you can hide from us ? roverman,"tells-all".

|

|

|

|

Re: Ford style girdle

I think I'd buy one for my Olds if it were available.

It would be useful on a Buick and Olds 215, and on the Rover 3.5, 3.9 and 4.2. The 'Power Tuning' book talks about the problem with main cap fretting. This girdle would help with that. And, a fella could put some crank scrapers on it. |

|

WedgeWorks1 Mike Perkins Ellicott City, Maryland (460 posts) Registered: 07/06/2008 08:07AM Main British Car: 1980 Triumph TR8 3.5 Litre Rover V8 |

Re: Ford style girdle

We will see how the caps look at the area of the girdle and go from there. I am sure on the final product it will be contours with the caps for a nice tight fit along with the area around the caps. We are even thinking about a tab that will go between the block and the cap for the side bolts on the bearing cap to really lock this thing in. Some maching of the cap and the block for a zero tolerance fit.

|

|

roverman Art Gertz Winchester, CA. (3188 posts) Registered: 04/24/2009 11:02AM Main British Car: 74' Jensen Healy, 79 Huff. GT 1, 74 MGB Lotus 907,2L |

Re: Ford style girdle

Mike, back in 83' I made billet caps from 7075 T6. No problem with expansion.With billet caps they could protrude up-into girdle-counter slots.No way to "dance" or "don't fret-it". I'm telling-all-Mike. roverman.

|

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6470 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Ford style girdle

Mike, did you use a cad/cam file to mill and drill that girdle? I need to make a 1/4" thick pan spacer and I figure I'll just run the extensions over to the main cap studs and stop there rather than crossing the caps. That'll tie the caps to the pan rail which should work quite well. But I'd just as soon not have to do the layout if it's already been done. There are a few guys on the Buick list who're also interested.

Jim |

|

WedgeWorks1 Mike Perkins Ellicott City, Maryland (460 posts) Registered: 07/06/2008 08:07AM Main British Car: 1980 Triumph TR8 3.5 Litre Rover V8 |

Re: Ford style girdle

Wotland-I knew you had more pictures. I have one that was just cut and will get on here.

|

|

Re: Ford style girdle

I made 3 girdle plates, studs waren an special order to J.Eales in UK to use the maximum thread lenght in the block.

Edited 1 time(s). Last edit at 12/20/2009 07:59AM by Wotland. |

|

Re: Ford style girdle

|

|

|

|

roverman Art Gertz Winchester, CA. (3188 posts) Registered: 04/24/2009 11:02AM Main British Car: 74' Jensen Healy, 79 Huff. GT 1, 74 MGB Lotus 907,2L |

Re: Ford style girdle

Girdle Guys, If using .25" steel, laser is most economical way to produce low quantities,(non-stamped). NOT plasma cut ! Aluminum girdles, .75"- up, water-jet is best. I have (2) CNC. mill's and I would pay for water-jet or laser.If I wanted to "nest" the main caps into the girdle, thats precision machining. roverman.

|

|

NixVegaGT Nicolas Wiederhold Minneapolis, MN (659 posts) Registered: 10/16/2007 05:30AM Main British Car: '73 Vega GT 4.9L Rover/Buick Stroker |

Re: Ford style girdle

Does the mains' fastener surface line up with the bottom of the block? This girdle looks like it just has clearance for the top of th main caps. OR is there some spacers to mate up to the fastener surface. Maybe this wouldn't matter if the studs were held secure by the girdle. Is that what's happening here?

|

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6470 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Ford style girdle

We had a big discussion about this over on V8Buick, most guys wanted to machine the caps apparently but how do you hold them in the block to do that? (and if they aren't machined in place they will never be exactly right) Plus, unless you align bore the block after the caps are cut and the girdle is fitted nothing is going to fit exactly right anyway. Some liked the clearanced girdle. I think a 1/4" steel plate that bridges from the pan rails to the main studs is going to be as good as you need. Unless maybe you're building an F1 engine. Water jet cut, CR steel, none of this fancy blanchard grinding etc. No need to spend megabucks on it.

Jim |

|

roverman Art Gertz Winchester, CA. (3188 posts) Registered: 04/24/2009 11:02AM Main British Car: 74' Jensen Healy, 79 Huff. GT 1, 74 MGB Lotus 907,2L |

Re: Ford style girdle

Jim, First question. Is 350 sbb " Y" skirted like its predecsssors? Whats the plan for evenly preloading each cap in a vertical plane. Will your un-ground plate be flat enough to evenly pre-load caps. FWIW. laser-cut should be less expensive than water-jet with no measurable distortion. Good Luck, roverman.

|

|

BlownMGB-V8 Jim Blackwood 9406 Gunpowder Rd., Florence, KY 41042 (6470 posts) Registered: 10/23/2007 12:59PM Main British Car: 1971 MGB Blown,Injected,Intercooled Buick 340/AA80E/JagIRS |

Re: Ford style girdle

Yeah, the blocks are very similar except for being iron instead of aluminum. Some differences in oil passages, some differences in water ports, and of course the deck height, main journal and bore size. That's about it. You have to shim between the girdle and spotface on the main caps no matter what you do unless you cut down the pan rail by a significant amount or replace the main caps with custom made ones, and the commonly agreed best practice is to shim a few thousandths proud, say .003-.005 depending on your girdle thickness and condition of the pan rail. So right there you're throwing away that expensive blanchard grinding job. No point in it. CR is typically flat to less than .001 anyway and if you grind it you warp it so what's the point? The CR is already going to be as flat as the pan rails. That's not your precision mating surface anyway, it's just a clamp and a stabilizer.

Jim |

Sorry, only registered users may post in this forum.